Mindblown: a blog about philosophy.

-

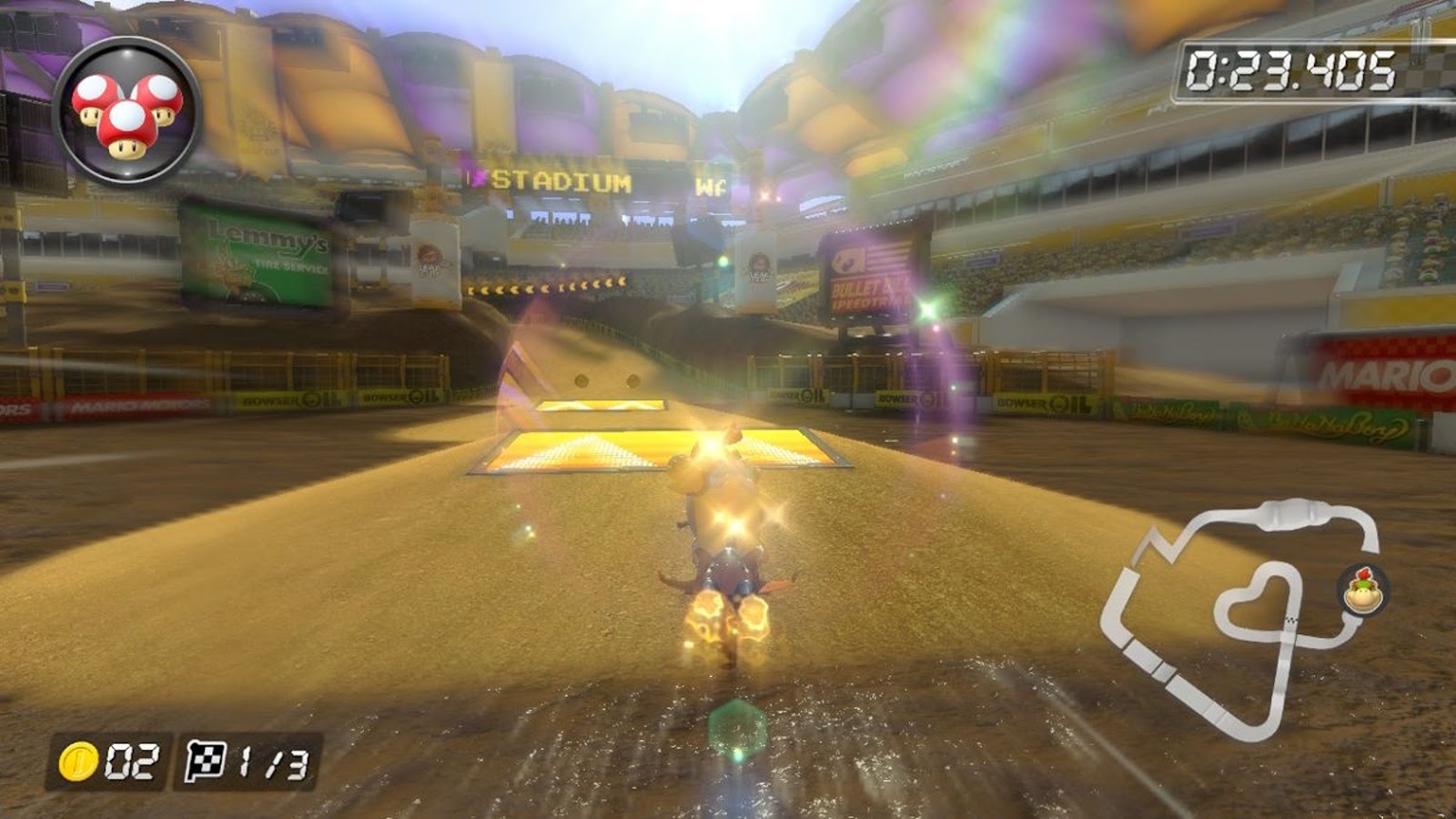

The Fastest Car In Mario Kart 8 Deluxe For Online Play

To find the fastest car for online play in Mario Kart 8 Deluxe, you need to have a good understanding of the game and why having the fastest car is so crucial. That’s why we are starting with an introduction to Mario Kart 8 Deluxe before delving into the importance of having the fastest car…

-

Tips For Playing Mario Kart 8 Like A Pro

How Many People Can Play Mario Kart 8 To understand how many people can play Mario Kart 8 like a pro, you need to know the factors affecting the number of players and the maximum number of players on different consoles. In this section, we’ll introduce you to these sub-sections and provide you with a…

-

Secrets To Getting Gold Glider In Mario Kart 8

The Gold Glider is a must-have item in Mario Kart 8. Beautiful golden finish, it gives your kart an extra boost and enhances your racing experience. Let’s dive deeper into its advantages. Benefit Requirement Increases Mini-Turbo Boost Time Collect Coins in Grand Prix Races to Unlock Increases Speed After Jump Boosting Get a minimum of…

Got any book recommendations?